Blowout Preventers (BOPs) are critical safety devices used in the oil and gas industry to prevent uncontrolled releases of hydrocarbons during drilling operations. These devices play a crucial role in maintaining the safety of drilling personnel, equipment, and the environment. The structure of a BOP is complex, with various components working together to effectively seal the wellbore and control pressure in the event of a blowout. In this article, we will explore the structure of a Blowout Preventer in detail, examining its components, functions, and the importance of each part in preventing accidents.

A Blowout Preventer is a large, high-pressure safety valve that is installed at the top of an oil or gas well during drilling operations. Its primary function is to prevent blowouts — the uncontrolled release of oil or gas from a well — by sealing the wellbore when necessary. BOPs are typically found on offshore drilling rigs, onshore rigs, and in well-servicing operations.

A blowout is a dangerous and potentially catastrophic event where the pressure in the well exceeds the capacity of the well’s casing, allowing oil, gas, or other fluids to escape uncontrollably. Blowout Preventers are designed to control this pressure and prevent such occurrences, ensuring the safety of workers and the surrounding environment.

The Blowout Preventer is made up of several key components, each of which plays a specific role in the prevention and management of blowouts. Below, we will look at the essential parts of a BOP and their functions:

1. BOP Body (Housing)

The BOP body or housing is the large, cylindrical structure that contains the internal components of the BOP. It is typically made of high-strength steel to withstand the immense pressure during drilling operations. The body serves as the main frame, housing the various seals, rams, and valves that make up the Blowout Preventer.

The body is designed to accommodate multiple sets of rams, shear rams, and other components, which can be activated to seal the wellbore in the event of a blowout. Depending on the specific requirements of the drilling operation, the BOP body can come in various sizes and configurations.

2. Rams

Rams are mechanical devices that form the core sealing mechanism within a Blowout Preventer. They are activated to close the wellbore when necessary, and they come in various types to handle different situations.

Blind Rams: Blind rams are used to seal off the wellbore completely when no pipe is inside. They create a solid seal, preventing the escape of fluids.

Pipe Rams: Pipe rams are designed to seal around a pipe that is passing through the BOP. They have cutouts or grooves that match the diameter of the pipe to provide a secure seal.

Shear Rams: Shear rams are equipped with a cutting mechanism that allows them to slice through the drill pipe or other equipment in the wellbore to create a seal. These rams are essential in situations where the well needs to be sealed off, but the pipe may be obstructing the process.

Variable Bore Rams: These rams are adjustable and can seal off a range of pipe sizes, offering flexibility for different drilling scenarios.

Rams are typically powered by hydraulic systems that allow them to be opened or closed quickly when necessary. They are one of the most important components for controlling the wellbore in emergency situations.

3. Control Systems

A BOP is operated through a control system that is responsible for activating the rams, valves, and other components. The control system is typically hydraulic, utilizing high-pressure fluid to move the various parts of the BOP.

There are two main types of control systems:

Choke and Kill Line Control: This system allows operators to circulate fluids or kill fluids into the wellbore to control the pressure or to kill the well in case of a blowout.

Annular Control: The annular BOP features an elastomeric seal that can close around the drill pipe or even seal the wellbore when no pipe is present.

These control systems are usually managed from the rig’s control room, where operators can monitor and adjust the status of the BOP in real time.

4. Annular Preventer

The annular preventer is a unique component of a BOP that is capable of sealing the wellbore even in the absence of a pipe. It uses a rubber-like sealing element that can expand and contract to form a seal around the pipe, casing, or the open wellbore. The annular preventer is typically used in situations where no pipe is present or to control wellbore pressure during drilling.

The annular preventer is often considered the primary backup for sealing the well when the rams are unable to do so, and it is activated by hydraulic pressure, just like the rams.

5. Pressure Relief Valve

In a Blowout Preventer system, maintaining balanced pressure is essential for preventing accidents. The pressure relief valve is designed to release excess pressure from the system, ensuring that the BOP does not become over-pressurized and fail. It is a safety mechanism that helps prevent further complications, particularly during high-pressure situations.

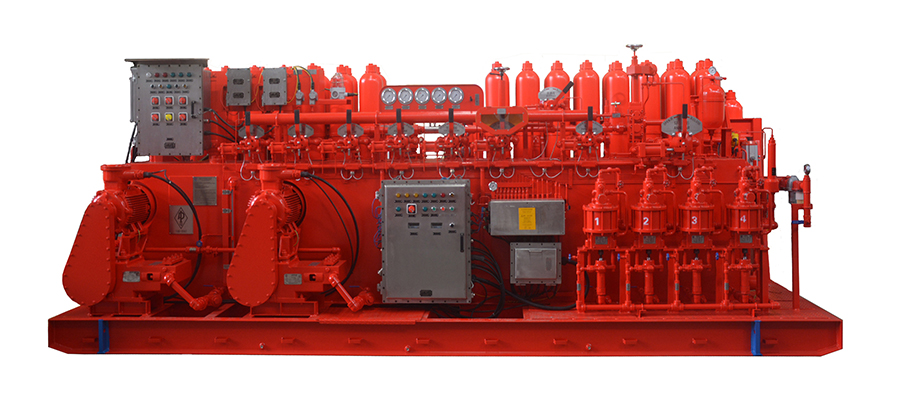

6. BOP Stack

The BOP stack refers to the entire assembly of BOP components, including the body, rams, annular preventers, and control systems. The BOP stack is typically installed on the wellhead, which is the equipment at the top of the well that manages all operations associated with the well. The stack’s primary purpose is to control the flow of hydrocarbons and other fluids from the well.

The BOP stack is modular, meaning that it can be customized to fit different types of drilling operations. It is designed to be highly flexible, with components that can be added or removed as needed.

The primary function of a Blowout Preventer is to prevent blowouts and control pressure. However, its operations extend beyond just sealing the well. The functions of a BOP include:

Sealing the Well: In the event of high pressure, the BOP seals the well to prevent the escape of fluids and gases.

Managing Well Pressure: The BOP helps control pressure within the wellbore to prevent the well from becoming over-pressurized.

Allowing for Well Control: The BOP system provides the ability to "kill" the well by injecting kill fluids or circulating fluids to control the pressure.

Providing a Secondary Barrier: The BOP serves as a secondary barrier that works in conjunction with the well casing to control pressure and prevent blowouts.

The structure of a Blowout Preventer is of utmost importance because it ensures the safety and reliability of drilling operations. A properly functioning BOP can prevent catastrophic blowouts, protecting workers, drilling equipment, and the environment. The different components, such as the rams, control systems, and annular preventers, each serve a specific function that contributes to the overall effectiveness of the BOP system.

Additionally, the BOP must be designed to withstand extreme pressures and environmental conditions. Offshore rigs, for example, require BOPs that are capable of handling the immense pressure of deepwater drilling, while onshore operations may involve different pressure requirements. The design and construction of the BOP, therefore, must be tailored to meet the specific needs of the operation.

The structure of a Blowout Preventer is highly specialized, with various components that work in tandem to ensure well control and prevent dangerous blowouts. By understanding the individual parts and their functions, it becomes clear how critical these devices are in maintaining safety during drilling operations. Given their importance, regular maintenance and testing of BOP systems are crucial for ensuring their reliability and functionality. As drilling technology advances and new challenges arise, the design and function of Blowout Preventers will continue to evolve, further enhancing the safety of oil and gas operations.

By continuing to use the site you agree to our privacy policy Terms and Conditions.