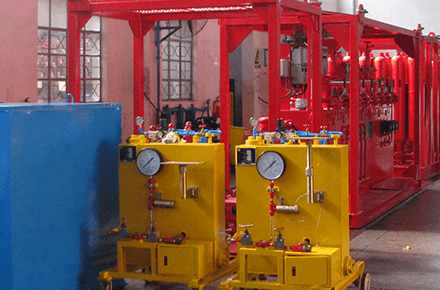

Dongsu's BOP control system has significant advantages in the industry, which makes it stand out in the market competition and provides reliable guarantee for oil and gas drilling operations. The following is a detailed analysis:

Advanced technology and materials: It is manufactured using advanced technology and high-quality materials, with stable and reliable performance. It can operate normally in various harsh working environments, such as high temperature, high pressure, and highly corrosive oil and gas production environments. It can effectively respond to the challenges brought by complex working conditions, ensure long-term stable operation of equipment, reduce the risk of downtime caused by equipment failure, and ensure the continuity of drilling operations.

Fast response and precise control: It has the ability to quickly respond and accurately control the action of the BOP system. In the face of emergencies, such as sudden changes in downhole pressure, it can respond quickly, close or adjust the BOP in time, prevent blowout accidents, accurately control the wellhead pressure, and ensure operation safety.

Diverse and adjustable functions: The control function is flexible, and various operations and adjustments can be performed as needed to realize the opening, closing, pressure control and other functions of the blowout preventer, adapting to different working requirements and wellhead conditions. For example, under different formation pressures, well depths, drilling fluid density and other conditions, the working state of the blowout preventer can be effectively controlled.

Customized service: In addition to standard products, special types of blowout preventer control systems can be designed according to customer-specific needs to meet personalized operation needs, such as customized exclusive control systems for complex working conditions such as special geological structures and deep-sea drilling to improve system adaptability and operation efficiency.

Simple design: The operation interface is clear and easy to understand, the design is simple, and it is easy for workers to operate, which reduces the professional skill requirements for operators and reduces safety issues caused by operating errors. For example, through intuitive buttons, indicator lights and display screens, operators can quickly grasp the operating status of the equipment and operate it.

Efficient command execution: Workers can control and monitor the status of the blowout preventer system through simple operations and instructions, improve work efficiency, and can quickly perform key operations such as shutting in wells in an emergency to ensure well control safety.

Good maintenance performance: easy to inspect and maintain, convenient for staff to carry out daily inspections, regular maintenance and troubleshooting, such as reasonable equipment layout, easy access and disassembly of key components, convenient cleaning, lubrication, replacement of wearing parts and other maintenance work.

Fault diagnosis and alarm function: equipped with fault diagnosis system and automatic alarm function, it can detect and prompt potential problems of equipment in time, help maintenance personnel quickly locate fault points, reduce maintenance time and cost, such as sensors monitor equipment operating parameters in real time, and immediately issue an alarm and display fault information once an abnormality occurs.

Applicable to various climates and geographical conditions: rich product models, more than 70 types, and a variety of control objects (2-15), suitable for various harsh climates and geographical conditions on land and at sea around the world, such as high temperature in deserts, severe cold in polar regions, and humid oceans, ensuring the safety of drilling operations in different regions and environments.

Meeting special environmental requirements: Special environmental factors are fully considered during the design and manufacturing process, such as wind and sand resistance, salt spray corrosion resistance, earthquake resistance, etc., and targeted protection and optimization of the equipment are carried out to ensure the stable operation of the system in extreme environments and improve the overall reliability and durability of the equipment.

Long-term industry accumulation: As one of the earliest manufacturers of ground-mounted blowout preventer control systems in China, it has more than 40 years of industry experience and has accumulated rich practical experience in product research and development, production, installation, commissioning and after-sales service. It can better understand customer needs, provide professional solutions, and deal with various technical problems.

Multiple authoritative certifications: Passing multiple international authoritative certifications, such as API Spec Q2, ISO 14001, ISO 145001, API 16D, API 16C, etc., indicates that the products and services meet international high standards in quality management, environmental protection, occupational health and safety, and the product quality and management system are internationally recognized, which enhances customer trust.

Flexible leasing service: Provide long-term or short-term professional equipment leasing services, flexibly arrange leasing time according to customer project cycle and needs, and provide after-sales maintenance and inspection services to ensure that the leasing equipment is always in good condition during use, provide customers with economical and convenient equipment use solutions, and reduce customers' equipment procurement costs and financial pressure.

Technical upgrading and transformation professional: According to customer requirements and industry development trends, provide equipment upgrading and transformation solutions, through in-depth research and communication, use professional technical teams to provide customers with personalized upgrading services, improve equipment performance and functions, extend equipment service life, so that customers' equipment always maintains advancedness and competitiveness, and adapts to changing operational needs.

Comprehensive maintenance service: Professional technical teams implement comprehensive maintenance services, covering equipment such as blowout preventer stacks, control systems and throttling manifolds. Maintenance content includes performance testing, fault repair, optimization and adjustment, etc., effectively improving equipment operation efficiency, reducing production costs, reducing the probability of safety accidents and production technology failures, and ensuring customers' production operations are safe, stable and efficient.

Recertification service specifications: Assist customers to regularly maintain and inspect equipment in accordance with relevant domestic and international standards, issue accurate inspection reports and certificates based on the actual situation of the equipment, ensure that the equipment meets the standard requirements, provide guarantee for the safe operation of the equipment in the next service cycle, and help customers standardize equipment management processes to meet industry regulatory requirements.

By continuing to use the site you agree to our privacy policy Terms and Conditions.