_

The high pressure test unit equipment is suitable for the hydraulic test of BOP stack, Choke manifold, Casing head, Pipe parts, Valve parts or other bearing parts used in well control equipment in oil drilling.

+

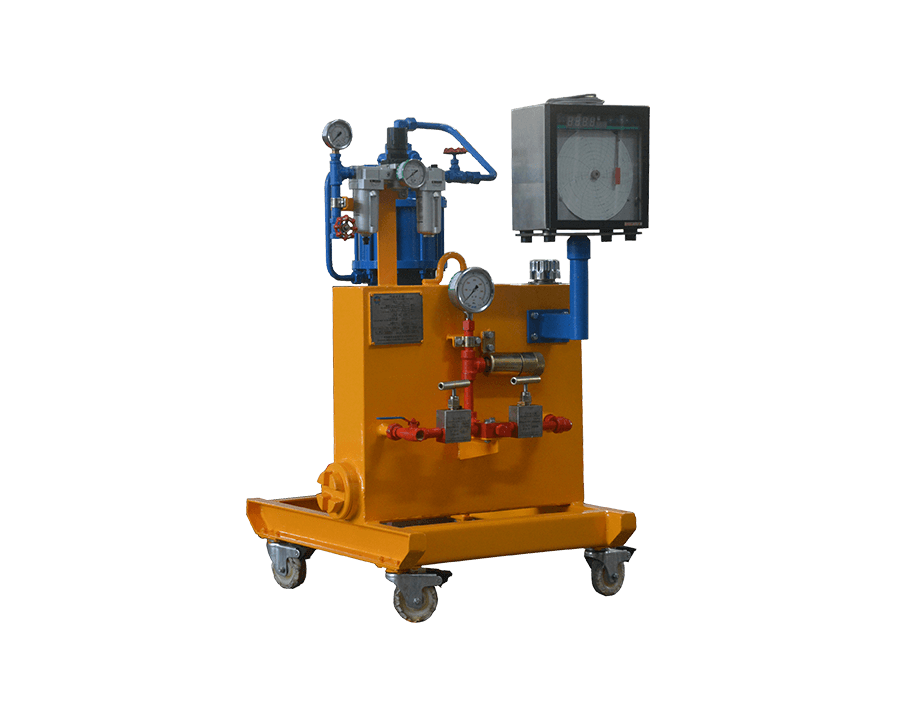

QST,DQST and DST Series Pneumatic, Electro pneumatic and Electric Pressure Test Unit(18 types).

+

In 1982, DONGSU's first high pressure test unit equipment was manufactured. We Deeply cultivate the well control industry for more than 40 years, with mature technology and stable quality.

Pneumatic pressure test unit High reliability Convenient maintenance High mechanical efficiency Running stability Compact structure

Pneumatic pressure test unit High reliability; Convenient maintenance; High mechanical efficiency; Running stability; Compact structure Running stability Compact structure

Electric pressure test unit High reliability; Convenient maintenance; High mechanical efficiency; Running stability; Compact structure Running stability Compact structure

Well Control Pressure Test Truck High reliability Convenient maintenance High mechanical efficiency Running stability Compact structure

5 advantages of high voltage test cells can include

The high-voltage test unit has the ability to generate and control high voltage, and can provide a stable high-voltage environment in scenarios where high-voltage testing is required. It can meet various testing needs and ensure the accuracy and reliability of testing.

High-voltage test units usually have multiple testing functions and can perform different types of tests, such as pressure testing, leakage testing, strength testing, etc. It can meet the testing needs of different industries and fields and provide comprehensive testing support.

The high-voltage test unit uses advanced sensors and control technology, which can monitor and control test parameters in real time to ensure test accuracy. It can provide high-precision test results to help users accurately evaluate the performance of products or equipment.

The high-voltage test unit is equipped with safety protection measures, such as overvoltage protection, pressure relief protection, etc., to ensure safety during the test process. It can prevent accidents and protect the safety of testers and equipment.

The high-voltage test unit is designed to be simple and easy to use, with a friendly operation interface. It is usually equipped with an intuitive control panel and operation guide, allowing users to easily perform test operations and reduce the occurrence of human errors.

High pressure test unit equipment are used for electric hydrostatic test pumps, BOP stacks, choke and kill lines, Christmas trees and any other equipment requiring high pressure static testing.

As a high pressure test unit manufacturers and suppliers, we specialize in providing reliable and accurate testing solutions to a wide range of industries. Each piece of our high pressure test unit equipment is manufactured to the highest quality standards, using the latest technology and materials to ensure long-lasting performance and accurate results.

Hydraulic pump testing equipment and pneumatic pressure testing equipment are key components in high pressure testing equipment. Their role is to provide the required test pressure and precise test data.

Hydraulic Pump Testing Equipment: Hydraulic pump test equipment is used to test the performance and functionality of hydraulic pumps that generate high pressure for various applications. This equipment helps the hydraulic pump to run normally, it can measure various parameters such as the flow rate, pressure, temperature and viscosity of the hydraulic oil, and can be used to check the pressure relief valve, seals and other components of the hydraulic pump.

Pneumatic Pressure Testing Equipment: Pneumatic test equipment is used to test the performance and functionality of pneumatic systems that generate high pressures in various applications. The device helps ensure proper functioning of pneumatic systems by measuring various parameters such as air flow, pressure, temperature and humidity. It can also be used to check relief valves, seals and other components of pneumatic systems.

Electric Pressure Test Unit: Equipment for testing the stress rating and integrity of various components and systems.

_

It is mainly used to test the pressure resistance of drilling tools and pipes to prevent leakage or damage due to excessive pressure during drilling and ensure the safety of drilling operations. At the same time, it can also be used for quality inspection of new equipment and regular maintenance testing of old equipment.

+

They can usually withstand extremely high pressures, the specific values of which vary depending on the model, and can generally reach tens of thousands of psi. They are suitable for complex drilling scenarios such as deep wells, ultra-deep wells, and high-pressure oil and gas wells.

+

Common test media include drilling fluid, water, nitrogen, etc. Different test media have different effects on drilling equipment. For example, drilling fluid may corrode the equipment, while nitrogen is relatively safe. When choosing a test medium, you need to consider factors such as the material of the equipment, test requirements, and impact on the environment.

+

The drilling site environment is complex, and attention should be paid to the protection and fixation of the equipment to prevent damage to the equipment due to vibration, collision and other factors. At the same time, the safety of the test area should be ensured, and warning signs should be set up to prevent unauthorized personnel from entering. When conducting high-voltage tests, safety operating procedures must be strictly followed to avoid safety accidents.

By continuing to use the site you agree to our privacy policy Terms and Conditions.