Guangzhou Dongsu Petroleum D&E Equipment Co., Ltd. is a pioneering leader in China’s surface BOP control system manufacturing. Since the early 1980s, we have spearheaded the R&D, design, and production of surface BOP control systems, pneumatic pressure test units, and choke manifold control panels—solidifying our reputation as an industry specialist with decades of expertise. To deliver seamless post-sales support, we established a dedicated Technical Service & Training Center in 2017, integrating training, maintenance, testing, and retrofitting for efficient, high-quality service.

Our strength lies in uncompromising quality and technical prowess: a team of over 30 senior engineers specializing in product R&D and design, paired with strict quality control protocols, advanced component/whole-machine inspection equipment, and seasoned QC professionals. Our sprawling 20,000㎡ modern production & assembly base houses more than 300 sets of state-of-the-art processing machinery, including five-axis machining centers, high-precision grinders, and CNC machining centers—ensuring precision and reliability in every unit.

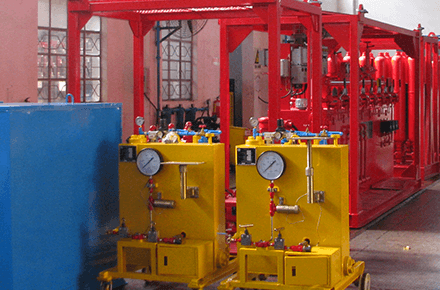

With a proven track record spanning global markets, we have supplied over 6,000 sets of surface BOP control devices, trusted by major oilfields and exploration drilling firms worldwide. Our products are exported to key oil & gas hubs including the US, the Middle East, Central Asia, South America, and Russia—testament to our compliance with international standards and customer confidence.

Driven by innovation, we continuously invest in technological upgrading of core products (BOP control systems, choke manifold control panels, high-pressure test units). Notably, we pioneered China’s first wireless remote-controlled BOP control system—successfully deployed at the Tarim Oilfield and proven to deliver exceptional safety and reliability in real-world operations.