The relevant data about operational process, alarm message, pressure and temperature of BOP Control System and Choke Manifold Control System would be monitored and recorded in real-time. The data would be stored and the report could be generated automatically.

Learn More

There is a clear requirement in the industry standard about increasing electric anti-lifting function for BOP Control System, which is to avoid the occurrence of rams, casing or drilling pipe breaking accidents caused by lifting the drilling pipe after closing the BOP, so as to use wellhead equipment safely after sealing the well.

Learn More

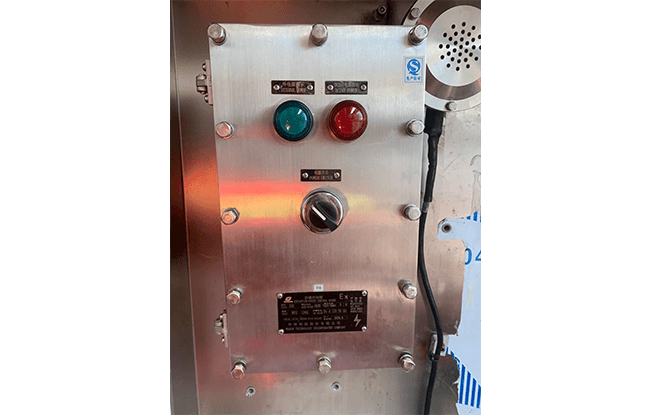

Pneumatic equipment is greatly affected by the control distance, ambient temperature and other factors. After modification, it would be more easier for maintenance, more stable for working, the system alarm function added to the equipment would make the equipment safer and more reliable.

Learn More

Staff have to evacuate and can not implement normal shut-in procedure in case of an emergency situation, Shearing Auxiliary /One-button Emergency Shut-in Function could be operated quickly by one person to attain rams shearing or shut-in.

Learn More

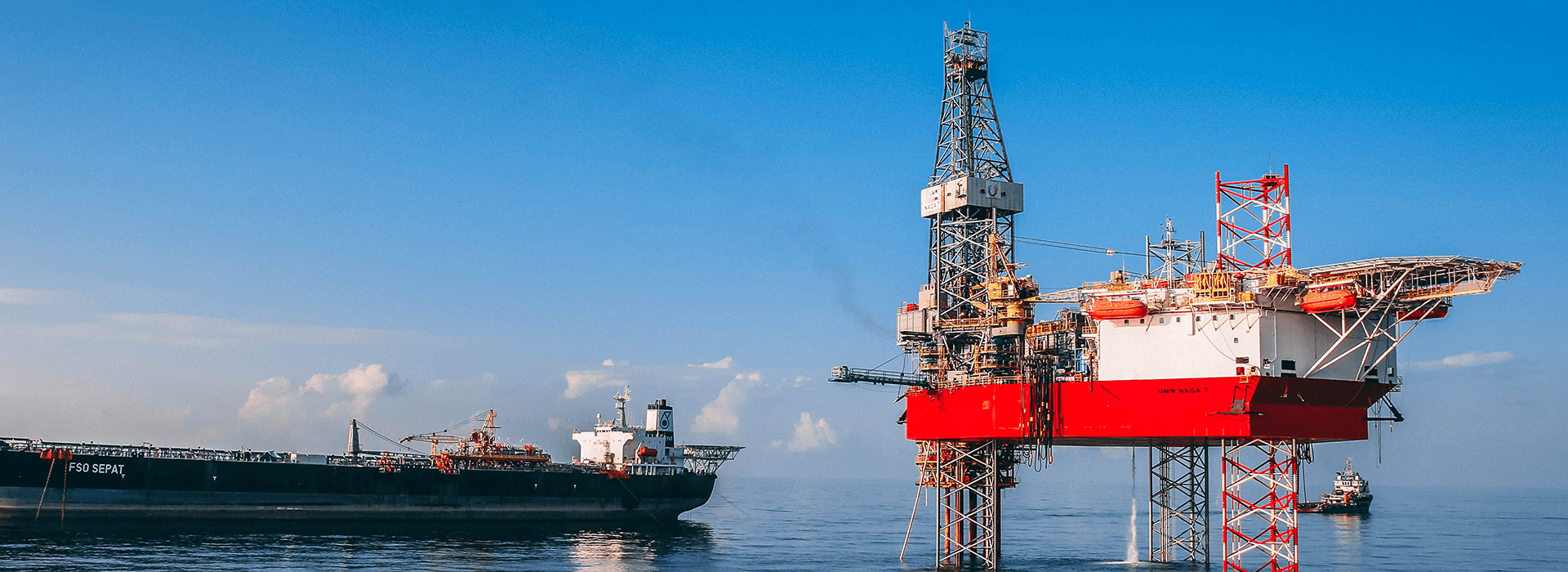

Upgrading and modification for well control equipment by increasing relevant hardware and operation monitoring system on site, in order to accomplish Cloud Services remote operation, data recording, equipment information management, fault judgment and analysis on well site, etc, which could be connected to Dongsu Digital Remote Management System or customer management system.

Learn MoreBy continuing to use the site you agree to our privacy policy Terms and Conditions.