Blowout preventers (BOPs) are critical safety devices used in the oil and gas industry to prevent uncontrolled release of reservoir fluids during drilling operations. These devices play a key role in protecting both personnel and equipment from potentially catastrophic blowouts. BOPs act as the last line of defense against well control incidents, ensuring operational safety in both onshore and offshore drilling activities.

There are two main types of blowout preventers: ram blowout preventers and annular blowout preventers. Each type serves a distinct function and is often used in conjunction with the other to provide multiple layers of protection. In this article, we will explore the two types of BOPs, their working principles, advantages, and applications in the oil and gas industry.

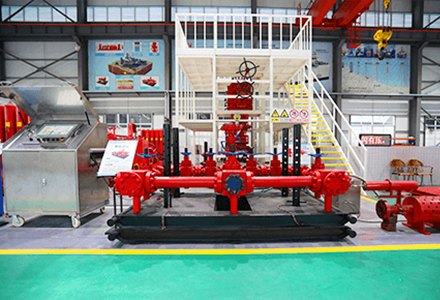

A ram blowout preventer is a type of BOP that uses steel rams to seal the wellbore. These rams move horizontally inside the preventer body to either completely close off the wellbore or seal around specific pipe sizes. Ram BOPs are typically installed on the wellhead or the BOP stack and are used in high-pressure drilling operations.

Ram BOPs come in different variations, depending on their specific functions:

Blind Rams: These rams are designed to completely seal the wellbore when no drill pipe is present.

Pipe Rams: These rams are shaped to close around a drill pipe, maintaining pressure control while allowing some operations to continue.

Shear Rams: These rams are equipped with blades that can cut through drill pipe, effectively shutting in the well in emergency situations.

Variable Bore Rams: These rams can seal around multiple pipe sizes, offering greater operational flexibility.

Provides a strong mechanical seal.

Suitable for high-pressure well control applications.

Different ram configurations offer flexibility in well control scenarios.

Requires specific rams for different pipe sizes.

Shear rams can permanently damage the drill string.

Cannot completely close the wellbore when a drill pipe is present unless shear rams are used.

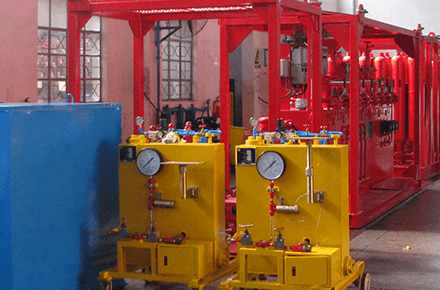

An annular BOP is a versatile type of blowout preventer that uses a rubber sealing element to control wellbore pressure. Unlike ram BOPs, annular BOPs can seal around a wide range of pipe diameters and even close the wellbore entirely when no pipe is in place. The sealing element expands inward when hydraulic pressure is applied, forming a tight seal around the drill string.

Annular BOPs consist of a donut-shaped elastomeric sealing element encased within a metal housing. When hydraulic pressure is applied, the rubber element constricts around the drill pipe or closes off the wellbore completely.

Advantages of Annular BOPs

Can seal around different pipe sizes without requiring multiple rams.

Provides a flexible sealing solution for well control operations.

Works effectively in combination with ram BOPs for enhanced safety.

Not as strong as ram BOPs in high-pressure conditions.

Sealing elements wear out over time and require regular replacement.

Less effective at cutting through drill pipe compared to shear rams.

|

Feature |

Ram BOP |

Annular BOP |

|---|---|---|

| Sealing Mechanism |

Steel Rams |

Elastomeric Seal |

| Pipe Compatibility |

Specific Pipe Sizes |

Multiple Pipe Sizes |

|

Cutting Capability |

Shear Rams Can Cut Pipe |

Cannot Cut Pipe |

| Pressure Handling |

High Pressure |

Moderate Pressure |

| Flexibility |

Limited |

High |

Both ram and annular BOPs are typically used together in a BOP stack, which consists of multiple preventers arranged to provide maximum well control capability. Annular BOPs are often positioned at the top of the stack for general well sealing, while ram BOPs are placed below to provide stronger, more specialized sealing and cutting functions.

BOPs are essential for maintaining well control during various stages of drilling, including:

Drilling operations: Preventing uncontrolled flow of fluids from the well.

Well testing: Ensuring pressure control while evaluating reservoir performance.

Well completions: Managing fluid flow as production tubing is installed.

Emergency shutdowns: Stopping blowouts in high-risk situations.

Blowout preventers are indispensable safety devices in oil and gas drilling operations. The two main types—ram BOPs and annular BOPs—serve distinct but complementary functions in controlling wellbore pressure. Ram BOPs provide strong mechanical sealing and cutting capabilities, while annular BOPs offer flexible sealing for a range of pipe sizes. Together, these devices form a critical line of defense against blowouts, ensuring safe and efficient drilling operations.

Understanding the functions, advantages, and limitations of these BOPs helps drilling professionals make informed decisions in well control management, ultimately enhancing operational safety and efficiency.

By continuing to use the site you agree to our privacy policy Terms and Conditions.