In the oil and gas industry, safety is paramount. One of the most crucial pieces of equipment ensuring operational security is the blowout preventer (BOP). This device is designed to control well pressure and prevent the uncontrolled release of oil, gas, or other well fluids, known as a blowout. Blowouts can lead to catastrophic damage, environmental pollution, and loss of human life. This article will explore the function, types, and significance of blowout preventers in drilling operations.

A blowout preventer serves as a fail-safe mechanism in drilling operations, acting as a barrier between the wellbore and external environment. Its primary functions include:

Well Control: It maintains control over the well by sealing, controlling, or monitoring pressure fluctuations.

Preventing Blowouts: By closing off the wellbore in emergencies, it prevents the uncontrolled eruption of hydrocarbons.

Protecting Personnel and Equipment: It ensures the safety of workers and prevents damage to drilling rigs, pipelines, and surrounding infrastructure.

Environmental Protection: Containing blowouts helps prevent oil spills, fires, and air pollution.

Blowout preventers come in various types, each designed for specific drilling conditions and operational needs. The two primary categories are ram BOPs and annular BOPs.

Ram BOPs use steel rams that extend across the wellbore to create a mechanical seal. There are different kinds of rams for various applications:

Blind Rams: Used to completely seal the wellbore when no pipe is present.

Pipe Rams: Close around the drill pipe to restrict flow while allowing controlled operations.

Shear Rams: Designed to cut through the drill pipe and seal the well completely in emergencies.

Annular BOPs use a rubber sealing element that contracts around the drill pipe, casing, or even an open hole. These are highly versatile and can be adjusted for different pipe sizes, making them essential for primary well control.

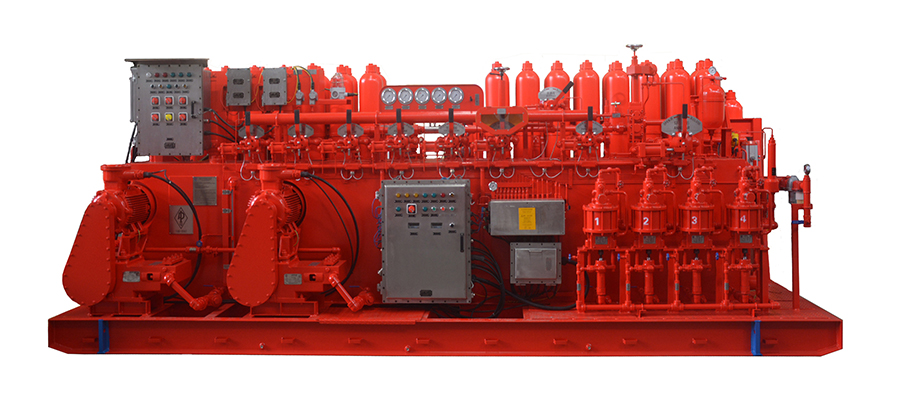

During normal drilling operations, the BOP remains open to allow the free movement of the drill pipe. However, if a sudden pressure surge occurs, the BOP is activated through hydraulic control systems. Depending on the situation, either the ram BOP or annular BOP engages to contain the pressure. In extreme cases, shear rams are deployed to sever the pipe and fully isolate the wellbore.

Blowout preventers play an indispensable role in ensuring operational safety and regulatory compliance. Some of their key benefits include:

Mitigating Risks: They help manage high-pressure formations and unexpected pressure kicks.

Compliance with Regulations: Oil and gas companies must adhere to strict safety guidelines, including maintaining functional BOPs.

Preventing Financial Losses: Blowouts can cause massive financial setbacks due to halted operations, legal fines, and cleanup costs.

Regular maintenance and rigorous testing of BOPs are critical for ensuring their reliability. Industry regulations require:

Pressure Tests: Periodic tests to check sealing integrity under various pressure conditions.

Functionality Checks: Ensuring hydraulic systems and mechanical components operate correctly.

Routine Inspections: Visual and non-destructive testing to identify wear and tear before failures occur.

Several high-profile blowouts in history underscore the importance of BOPs. One such incident is the Deepwater Horizon disaster in 2010, where a BOP failure contributed to one of the worst oil spills in history. This event led to increased scrutiny, stricter regulations, and advancements in BOP technology.

A blowout preventer is a critical safety device in oil and gas drilling, ensuring well control and protecting lives, the environment, and equipment. With ongoing advancements in BOP technology and stringent regulatory measures, the industry continues to enhance drilling safety. Proper maintenance, training, and adherence to safety protocols are essential in preventing blowout-related disasters.

By understanding what a blowout preventer does and how it functions, drilling companies can maintain safe and efficient operations in the challenging environments of oil and gas extraction.

By continuing to use the site you agree to our privacy policy Terms and Conditions.