Blowouts on oil rigs represent one of the most significant risks in the oil and gas industry. They occur when uncontrolled hydrocarbons surge to the surface, often resulting in catastrophic consequences. Understanding the causes of blowouts is crucial for enhancing safety protocols, minimizing risks, and protecting both workers and the environment. This article delves into the fundamental reasons behind blowouts, the mechanisms involved, and the preventive measures that can be implemented.

A blowout is an uncontrolled release of crude oil or natural gas from a well. This can happen when the pressure from the reservoir exceeds the pressure exerted by the column of fluid in the well. The sudden influx of hydrocarbons can lead to explosions, fires, and significant environmental damage, making blowouts one of the most dangerous incidents that can occur in oil drilling.

The Pressure Imbalance

One of the primary causes of a blowout is the pressure imbalance between the underground formation and the wellbore. When drilling, pressure is managed through the use of drilling mud, which helps to counteract the natural formation pressure. If the pressure in the formation increases unexpectedly or if the mud weight is insufficient, a blowout can occur.

Inadequate Mud Weight

Drilling mud plays a vital role in controlling well pressure. If the mud weight is too low, it may not exert enough hydrostatic pressure to prevent fluids from entering the wellbore. Conversely, using excessively heavy mud can lead to issues such as stuck pipe, making it crucial to maintain an appropriate mud weight throughout the drilling process.

Equipment Failures

Equipment failures can significantly contribute to blowout incidents. Various components on an oil rig are designed to prevent blowouts, and any malfunction can compromise safety.

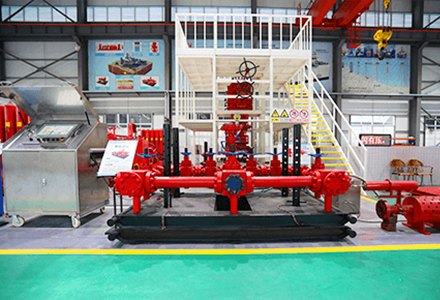

Blowout Preventers (BOPs)

Blowout preventers are critical safety devices designed to seal, control, and monitor oil and gas wells. They are activated to contain pressure during drilling operations. If a BOP fails due to mechanical failure, improper maintenance, or design flaws, it can lead to a blowout. Regular inspections and maintenance of BOPs are essential to ensure their reliability.

Other Equipment Malfunctions

Beyond BOPs, other equipment failures, such as issues with the drilling rig or the casing, can lead to blowouts. For instance, a compromised casing may allow formation fluids to escape into the wellbore. Ensuring all equipment is well-maintained and operational is crucial to preventing such incidents.

Human error is another significant contributor to blowouts. Decision-making in high-pressure situations can lead to mistakes that compromise safety.

Poor Communication

Effective communication among the drilling team is essential for safety. Miscommunication about pressure readings, mud weight adjustments, or drilling parameters can lead to insufficient control measures being implemented, ultimately resulting in a blowout.

Lack of Training

Inadequate training can also result in dangerous situations. Personnel must be thoroughly trained in operating safety equipment, understanding drilling dynamics, and recognizing signs of potential blowouts. Regular training sessions and drills can prepare the crew to respond effectively in emergencies.

Understanding the geology of the drilling site is critical in preventing blowouts. Unanticipated geological conditions can pose risks that may lead to blowouts.

Unexpected Formation Pressure

Sometimes, drillers encounter formations with higher-than-expected pressure. This can happen due to geological formations that trap hydrocarbons under significant pressure. Proper geological surveys and analysis before drilling can help identify potential risks.

Natural Fractures

The presence of natural fractures in the rock can create pathways for fluids to escape from the formation, increasing the likelihood of a blowout. Comprehensive geological assessments, including seismic surveys, can help detect such features and inform drilling strategies.

Environmental factors can also play a role in blowouts. Severe weather conditions, such as storms or high winds, can create challenges that impact drilling safety.

Weather Conditions

Harsh weather can hinder operations and lead to unsafe conditions. For example, strong winds or rough seas can affect drilling stability and increase the likelihood of equipment failure. Implementing weather monitoring systems and establishing protocols for adverse conditions can mitigate these risks.

Seismic Activity

In areas prone to seismic activity, the risk of blowouts may increase. Earthquakes can alter subsurface pressures and cause structural failures in wells. Conducting risk assessments in seismically active regions can help identify necessary precautions.

Preventing blowouts requires a comprehensive approach that includes technology, training, and effective management practices.

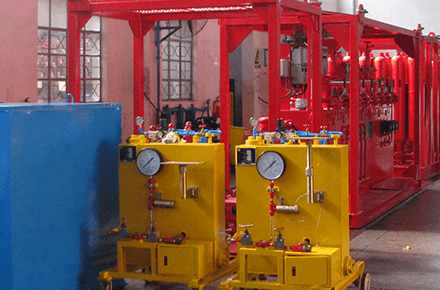

Enhanced Technology

Advancements in technology, such as improved BOP systems and real-time monitoring tools, can enhance blowout prevention. Utilizing sensors and data analytics can provide valuable insights into well conditions and alert operators to potential issues before they escalate.

Rigorous Training and Drills

Regular training and emergency drills are essential for ensuring that all personnel are prepared to respond to potential blowouts. These exercises should include simulated blowout scenarios, allowing the crew to practice their responses in a controlled environment.

Comprehensive Risk Assessments

Conducting thorough risk assessments prior to drilling can help identify potential hazards. This includes evaluating geological conditions, equipment reliability, and operational protocols to ensure that adequate safety measures are in place.

Blowouts on oil rigs are complex incidents driven by a combination of factors, including pressure imbalances, equipment failures, human error, geological conditions, and environmental influences. By understanding the causes of blowouts and implementing comprehensive safety measures, the oil and gas industry can significantly reduce the risks associated with drilling operations. Continuous improvement in technology, training, and risk management practices will play a vital role in preventing blowouts and ensuring the safety of workers and the environment.

By continuing to use the site you agree to our privacy policy Terms and Conditions.