In the high-stakes environment of oil and gas exploration, safety is not just a regulatory requirement—it's a mission-critical priority. Among the many layers of engineering and safety mechanisms built into drilling operations, the Blowout Preventer (BOP) stands as one of the most essential. Positioned at the wellhead, a BOP serves as a primary line of defense against uncontrolled releases of oil, gas, and other wellbore fluids. Its function is not merely reactive but integrative—safeguarding workers, protecting equipment, and preventing environmental disasters. This article explores the pivotal role of the blowout preventer in modern drilling operations, covering its functions, components, operational mechanisms, and contributions to overall well control.

A Blowout Preventer is a specialized, high-pressure safety device installed at the top of a wellbore during drilling, workover, or completion operations. Its core purpose is to seal the well in the event of an unexpected influx of pressurized formation fluids—commonly referred to as a "kick"—to prevent a blowout.

A blowout occurs when high-pressure hydrocarbons escape from the well uncontrollably, leading to explosive events, environmental spills, or equipment failure. The BOP is designed to control this pressure, allowing time for corrective action and protecting both personnel and assets.

The operation of a BOP revolves around three primary actions: sealing the wellbore, containing well pressure, and diverting dangerous flows safely away from personnel and sensitive equipment.

Sealing the Well: When activated, the BOP uses either annular or ram elements to form a seal around the drill string or across an open hole.

Containing Pressure: The closed BOP holds back high-pressure fluids until the pressure can be safely reduced using well control procedures.

Diverting Flow: In some configurations, the BOP includes valves and lines to divert fluids to a choke manifold or flare stack for safe handling.

These mechanisms are often controlled via a remote panel, allowing operators to respond quickly without exposing themselves to danger.

Blowout preventers are broadly classified into two major types, each with its specific structure and operational advantages: ram-type BOPs and annular-type BOPs.

Ram BOPs utilize steel rams that move horizontally to close off the wellbore. They are modular and can be configured with different ram types for various functions:

Pipe Rams: Seal around a drill pipe, maintaining pressure integrity while allowing the pipe to stay in place.

Blind Rams: Close off an open hole when no pipe is present.

Shear Rams: Capable of cutting through the drill pipe and sealing the well in extreme emergencies.

Variable Bore Rams: Adapt to seal around multiple pipe sizes, increasing operational flexibility.

These rams offer robust sealing and are often stacked together in a BOP stack for redundancy and enhanced safety.

Annular BOPs use a circular, rubber sealing element that contracts inward when hydraulically actuated, forming a flexible seal around varying shapes—drill pipe, casing, or even an empty hole.

Versatility: Ideal for dynamic drilling operations where different tools pass through the wellbore.

First Line of Defense: Often used as the topmost BOP in a stack, providing rapid initial control during pressure surges.

Annular preventers offer adaptability but are typically backed by ram preventers for full redundancy.

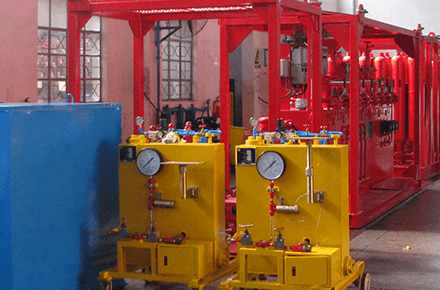

The role of the BOP does not stand alone—it is deeply integrated into a broader well control system, which includes:

Accumulator Units: Provide hydraulic power to operate the BOP even in the event of rig power failure.

Control Panels: Allow manual or automatic actuation of the BOPs, either on-site or remotely.

Pressure Monitoring Devices: Real-time sensors track bottomhole and surface pressure, enabling preemptive actions.

Choke and Kill Lines: Provide controlled circulation paths to manage pressure during well control events.

In modern setups, digital integration and IoT sensors allow for automated response systems, data analytics, and improved decision-making during high-pressure scenarios.

The criticality of BOP systems becomes even more apparent when comparing offshore and onshore drilling operations.

Offshore environments, especially in deepwater operations, present extreme risks due to high formation pressures, limited escape routes, and complex logistics. Subsea BOPs, often located on the seabed, must:

Operate under high pressure and low temperatures.

Be remotely controlled from the rig via umbilicals or wireless systems.

Offer multiple redundancies to handle failures without human intervention.

A malfunction in such environments can lead to catastrophic consequences, as witnessed in past industry disasters.

While more accessible, onshore drilling operations still require stringent well control measures. Surface BOP stacks are used here and can be maintained more easily, but must still adhere to regulatory standards such as API 16A, ISO 13533, and regional codes depending on jurisdiction.

The deployment and maintenance of BOPs are governed by strict industry standards to ensure reliability and performance. These include:

API 16A: Covers the design, manufacturing, and testing of BOPs.

API RP 53: Provides guidelines for BOP system operation and maintenance.

ISO 13533: Offers international standards for BOP design and quality control.

Routine testing, certification, and inspection are mandatory. Non-compliance can lead to severe penalties, drilling shutdowns, or reputational damage.

Despite decades of development, challenges in BOP reliability persist due to:

High-pressure, high-temperature (HPHT) environments

Complex deepwater well architectures

Mechanical fatigue and corrosion

To address these challenges, the industry is embracing advanced materials, smart monitoring systems, and automated fail-safe mechanisms.

Emerging innovations include:

Self-diagnosing sensors for predictive maintenance

Digital twins to simulate BOP performance in real time

Remote-operated BOP units with AI-enhanced decision-making

These technologies aim to reduce human error, speed up response times, and increase the likelihood of a successful intervention during a blowout risk.

The Blowout Preventer is not merely a piece of hardware—it is a guardian of life, environment, and investment in oil and gas drilling. By offering robust, layered protection against uncontrolled formation pressures, the BOP provides confidence and operational stability in both conventional and unconventional drilling projects.

As exploration ventures into more complex and risk-prone territories, the role of the BOP will only grow in importance. Continuous innovation, stricter regulatory frameworks, and greater awareness of environmental responsibility will shape the next generation of blowout prevention systems—ensuring that drilling remains not just profitable, but safe and sustainable.

By continuing to use the site you agree to our privacy policy Terms and Conditions.