Oil blowout preventers (BOPs) are essential safety devices used in oil and gas drilling operations to control unexpected surges of pressurized formation fluids. Positioned at the wellhead, a BOP’s primary function is to prevent the uncontrolled release of hydrocarbons—commonly referred to as a "blowout"—by sealing, controlling, or diverting high-pressure wellbore fluids during drilling activities. These devices are fundamental to ensuring safety, protecting equipment, and mitigating environmental hazards in both offshore and onshore drilling environments.

A BOP is activated when there is an unanticipated influx of oil, gas, or water from the formation into the wellbore—commonly known as a "kick." In such events, rapid sealing of the wellbore is crucial to avoid a blowout. BOPs achieve this by deploying mechanical or hydraulic systems, depending on the design.

Hydraulic and Mechanical Activation: Blowout preventers are generally powered by hydraulic systems that allow remote and rapid actuation. Some systems are also equipped with mechanical fail-safes to operate in case of hydraulic failure.

Emergency Sealing with Shear Rams: In critical scenarios, shear rams can be engaged to cut through the drill string and completely seal the wellbore, isolating pressure and halting the release of fluids.

Blowout preventers are primarily classified into two major categories based on their sealing mechanism: Ram BOPs and Annular BOPs. Each type serves a unique role in managing various drilling conditions.

Ram BOPs use steel plungers ("rams") to seal the wellbore. These rams can be interchanged to suit specific operational requirements:

Pipe Rams: Designed to seal the wellbore around the drill pipe while allowing it to remain in place.

Blind Rams: These fully close the wellbore when no pipe is present.

Shear Rams: Capable of cutting through drill pipe and sealing the wellbore entirely in the event of an emergency.

Ram BOPs are known for their robust sealing capacity and are commonly stacked in various configurations to provide multi-level safety redundancy.

Annular BOPs feature a donut-shaped rubber sealing element that contracts inward when activated, forming a flexible seal around virtually any object in the wellbore—drill pipe, casing, or even open holes.

Versatility in Sealing: Their ability to adapt to irregular shapes makes annular BOPs ideal for dynamic drilling operations where different tools are frequently run through the wellbore.

Primary Sealing Role: Often used as the first line of defense, especially when precise control over the drilling environment is required.

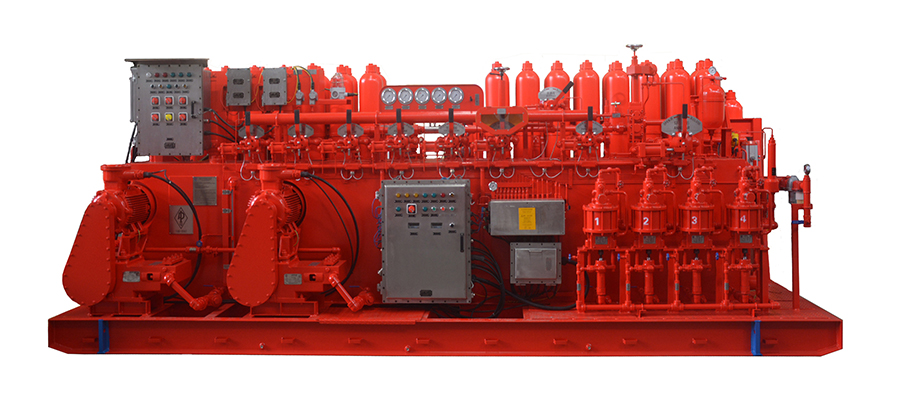

Modern blowout preventers are part of a larger, highly engineered BOP control system that allows operators to manage well pressure remotely and respond quickly to emergencies. This system typically includes:

Remote Control Panels: Located on the drilling rig and often in backup locations to allow for safe and immediate activation.

Accumulator Units: Store pressurized hydraulic fluid used to activate the BOP even in the event of power loss.

Pressure Sensors and Monitors: Continuously track wellbore pressure, enabling early detection of kicks.

Integration with real-time digital systems, including Internet of Things (IoT) devices and SCADA platforms, has enhanced operational safety by providing:

Automated Emergency Shutdowns: Systems can autonomously close the BOP in case of anomalies.

Data Analytics: Continuous data monitoring allows predictive maintenance and better response strategies.

Compliance with Industry Standards: Most BOP systems are built to meet or exceed stringent safety standards such as API 16A, which governs design and testing protocols.

While BOPs are critical in both offshore and land-based drilling operations, their complexity and scale differ based on the operational environment:

Offshore BOPs: Typically part of a subsea stack deployed on the seabed. These require advanced remote operation capabilities and must endure extreme pressure and temperature conditions.

Onshore BOPs: Installed at the surface and are generally more accessible for maintenance and inspection but still require stringent safety compliance due to high formation pressures.

The oil blowout preventer remains one of the most vital components in ensuring safety and operational integrity in the oil and gas industry. As exploration pushes into deeper and more geologically complex formations, the role of advanced BOP systems becomes even more critical. Innovations in materials, remote monitoring, automation, and real-time data integration are driving the evolution of BOPs, making them smarter and more reliable than ever before.

Operators, engineers, and regulators alike continue to emphasize BOP reliability as a cornerstone of responsible drilling practices—underscoring the device's essential role in environmental protection and worker safety.

By continuing to use the site you agree to our privacy policy Terms and Conditions.