Blowout preventers (BOPs) play a critical role in maintaining well control in drilling operations. These complex systems prevent the uncontrolled release of oil, gas, or fluids from a well, safeguarding lives, equipment, and the environment. Central to the operation of BOPs is the hydraulic control system, which uses specially formulated hydraulic fluids to power the components of the blowout preventer. In this article, we’ll explore the role of hydraulic fluids in BOP control systems, discussing their properties, importance, and the key factors to consider when selecting these fluids.

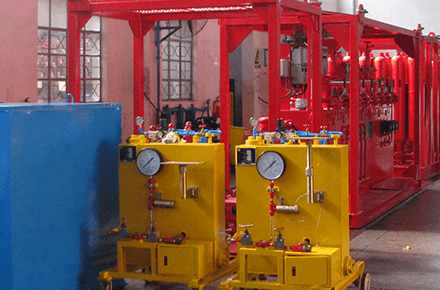

A BOP control system is a combination of valves, accumulators, and piping that allows the remote activation of a blowout preventer. These systems use hydraulic pressure to control the BOP, ensuring it can be deployed quickly during an emergency. The reliability of this control system depends heavily on the hydraulic fluid used, as it transmits the necessary force to operate the valves, rams, and annular preventers in the BOP.

Hydraulic fluids are the lifeblood of a BOP control system. They serve as the medium through which mechanical energy is transmitted, allowing the system to function smoothly and efficiently. When pressure is applied to the hydraulic fluid, it triggers movement in the BOP’s mechanical components, helping operators control the well and prevent blowouts.

The quality and performance of the hydraulic fluid are essential to the BOP system’s reliability. Inferior fluids can lead to system failures, corrosion, and even potential blowouts, putting lives and assets at risk. This makes it crucial to understand the specific requirements of hydraulic fluids in these high-stakes environments.

Several essential properties make hydraulic fluids suitable for use in BOP control systems. These properties ensure that the fluid performs reliably under extreme conditions. Here are the key attributes:

1. Viscosity

The viscosity of a hydraulic fluid determines its ability to flow through the control system. A fluid that is too thick may not circulate efficiently, while one that is too thin might not provide enough force to operate the BOP components. For optimal performance, hydraulic fluids used in BOP systems need to have stable viscosity across a wide range of temperatures.

2. Thermal Stability

BOP operations can involve extreme temperature changes. Hydraulic fluids must maintain their integrity and performance under both high and low temperatures. Thermal stability ensures that the fluid does not degrade or lose its lubricating properties when subjected to high heat during drilling operations or freezing temperatures in offshore environments.

3. Water Tolerance

Since many BOP control systems are used in offshore drilling, hydraulic fluids must be able to resist water contamination. Water can lead to emulsification, reduced lubrication, and even corrosion of critical components. Hydraulic fluids should have excellent water separation capabilities to prevent system failure in humid or wet conditions.

4. Lubricity

Lubricity refers to the fluid’s ability to reduce friction between moving parts. Adequate lubrication is crucial for the smooth operation of a BOP control system. Hydraulic fluids must be designed to protect the system's components from wear and tear, reducing the need for frequent maintenance and minimizing the risk of equipment failure.

5. Oxidation Resistance

Oxidation occurs when hydraulic fluid reacts with oxygen, leading to the formation of acids, sludge, and other contaminants that can compromise system performance. Oxidation-resistant hydraulic fluids are essential for BOP control systems, ensuring the fluid remains stable and effective for extended periods.

6. Corrosion Protection

The harsh environments in which BOP systems operate can lead to corrosion of metal components. Hydraulic fluids must contain anti-corrosion additives to prevent rust and degradation, extending the lifespan of the equipment and ensuring the BOP remains reliable during critical operations.

There are several types of hydraulic fluids that are commonly used in BOP control systems, each designed to meet specific performance requirements. The selection of the right fluid depends on various factors, including the operating environment, system design, and the type of BOP in use.

1. Water-Based Hydraulic Fluids

Water-based hydraulic fluids, such as water glycol solutions, are commonly used in BOP control systems. These fluids offer excellent fire resistance, making them a safe choice for offshore and high-risk environments. However, they require careful management to prevent corrosion and maintain water separation properties.

2. Mineral Oil-Based Hydraulic Fluids

Mineral oil-based hydraulic fluids are known for their superior lubricity and thermal stability. They are often used in onshore BOP control systems where the risk of fire is lower. However, these fluids may not offer the same level of fire resistance as water-based alternatives.

3. Synthetic Hydraulic Fluids

Synthetic hydraulic fluids provide enhanced performance in extreme temperature conditions. They offer excellent oxidation resistance, corrosion protection, and thermal stability, making them suitable for demanding drilling operations. Despite their higher cost, synthetic fluids are favored for their long-lasting performance and reduced maintenance requirements.

4. Environmentally Friendly Hydraulic Fluids

As environmental regulations become more stringent, there is an increasing demand for biodegradable and environmentally friendly hydraulic fluids. These fluids are designed to minimize environmental impact in case of a spill or leak. They offer similar performance characteristics to conventional fluids but are more eco-friendly, making them ideal for offshore and sensitive drilling locations.

Selecting the right hydraulic fluid for a BOP control system requires a thorough understanding of the operational conditions and specific performance needs of the system. Here are some key considerations:

1. Operating Temperature Range

The hydraulic fluid must be able to perform within the temperature range of the drilling environment. For offshore applications where temperatures can fluctuate significantly, it is crucial to choose a fluid with a wide operating temperature range.

2. Compatibility with System Materials

Not all hydraulic fluids are compatible with the materials used in BOP systems. Some fluids may cause seals or other components to degrade over time. It is essential to select a fluid that is compatible with the materials in the BOP control system to avoid premature wear and failure.

3. System Pressure Requirements

BOP control systems operate under high pressure, and the hydraulic fluid must be able to withstand these conditions without compressing or losing effectiveness. Fluids with high compressive strength ensure that the system maintains adequate force to control the blowout preventer in an emergency.

4. Fire Safety

In offshore drilling, fire safety is a primary concern. Water-based or fire-resistant synthetic fluids should be chosen for high-risk environments where the potential for fire or explosion exists.

5. Environmental Regulations

Many drilling sites, particularly offshore, are subject to stringent environmental regulations. Using environmentally friendly hydraulic fluids can help operators comply with these regulations while minimizing environmental impact.

Regular maintenance of the hydraulic fluid is critical to ensuring the long-term performance and reliability of the BOP control system. Over time, hydraulic fluids can become contaminated with dirt, water, or other particles that reduce their effectiveness. Regular monitoring of fluid quality and scheduled replacements are necessary to avoid system malfunctions.

1. Fluid Filtration

Contaminants such as dust, metal particles, and water can degrade hydraulic fluid quality and damage system components. Installing high-quality filters in the BOP control system can help remove these contaminants and extend the lifespan of the fluid.

2. Periodic Fluid Testing

Regular testing of the hydraulic fluid can identify issues such as oxidation, contamination, and viscosity changes. Early detection of problems allows operators to replace or treat the fluid before it compromises system performance.

3. Replacing Degraded Fluids

When hydraulic fluids begin to show signs of degradation, such as loss of viscosity, increased acidity, or contamination, they should be replaced promptly. Operating a BOP control system with degraded fluid increases the risk of system failure during critical operations.

Hydraulic fluids are an essential component of BOP control systems, ensuring the safe and reliable operation of blowout preventers in drilling environments. The right hydraulic fluid must have properties such as optimal viscosity, thermal stability, water resistance, and corrosion protection to meet the demanding requirements of these systems. Operators must carefully select fluids based on their system’s specific needs and maintain them regularly to ensure continued performance. By doing so, the safety, efficiency, and reliability of drilling operations can be significantly enhanced.

By continuing to use the site you agree to our privacy policy Terms and Conditions.