Ensuring the integrity and safety of oil and gas wells is of paramount importance in the energy industry. One crucial component that plays a vital role in this regard is the Blowout Preventer (BOP) control unit. This article explores the significance of BOP control units and how they safeguard drilling operations, highlighting their key features and benefits.

The BOP control unit is an essential device used in oil and gas drilling operations. It is responsible for controlling the Blowout Preventer, a critical safety mechanism that prevents uncontrolled release of hydrocarbons from the well.

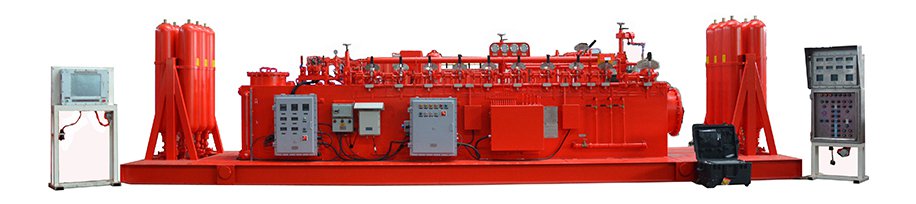

The BOP control unit comprises various components, including hydraulic systems, control panels, and monitoring instruments. These components work together to provide precise control and monitoring of the BOP stack, ensuring its optimal functioning.

The primary purpose of the BOP control unit is to prevent blowouts, which can lead to catastrophic accidents and environmental disasters. By maintaining constant pressure on the wellbore and sealing it off in case of an emergency, the BOP control unit acts as a reliable barrier against the uncontrolled release of oil or gas.

During drilling operations, maintaining appropriate well pressure is crucial. The BOP control unit enables operators to regulate and control the pressure within the wellbore, ensuring it remains within safe limits. This helps prevent formation damage, well instability, and potential blowouts.

Modern BOP control units are equipped with advanced monitoring and control systems. These systems provide real-time data on various parameters such as pressure, temperature, and flow rate, allowing operators to make informed decisions and take immediate action if any abnormalities are detected.

BOP control units are designed with redundancy in mind, ensuring that even in the event of a failure in one component, the system remains operational. This redundancy enhances the reliability of the control unit, minimizing the risk of equipment malfunction during critical operations.

In today's digital age, remote operation capabilities have become increasingly important. BOP control units can be remotely monitored and controlled, enabling operators to make adjustments and respond promptly to any emergencies, even from a remote location.

The BOP control unit stands as the guardian of oil and gas wells' integrity and safety. With its advanced features, precise control, and real-time monitoring capabilities, it plays a crucial role in preventing blowouts and ensuring the smooth operation of drilling activities. As the energy industry continues to evolve, the BOP control unit remains an indispensable component in safeguarding drilling operations and protecting the environment.

By continuing to use the site you agree to our privacy policy Terms and Conditions.