In the realm of oil and gas exploration, safety is of utmost importance, particularly in high-pressure drilling operations. Blowout preventers (BOPs) are vital components in ensuring the safety and control of drilling processes. Among these, the annular BOP stands out as a critical device designed to manage and control wellbore pressure. This article delves into the concept of an annular BOP, its functionality, components, and significance in the oil and gas industry.

A blowout preventer is a specialized valve system installed at the wellhead of an oil or gas well to manage extreme wellbore pressure. BOPs prevent the uncontrolled release of oil, gas, or drilling fluids—a phenomenon known as a blowout. Blowouts can lead to catastrophic damage to equipment, environmental hazards, and threats to human life.

Ram BOP: Utilizes horizontal rams to seal the wellbore.

Annular BOP: Employs a flexible sealing mechanism to close the wellbore.

Both types are typically used in tandem to provide comprehensive well control.

An annular BOP is a type of blowout preventer designed to seal the wellbore using a flexible, doughnut-shaped rubber sealing element. Unlike ram BOPs that rely on rigid mechanisms, the annular BOP provides a versatile and adaptable seal around various drill pipe sizes, tubing, or even an open wellbore.

This flexibility makes the annular BOP an invaluable tool in drilling operations where varying conditions and equipment dimensions are encountered.

The annular BOP comprises several key components, each serving a specific function:

1. Body

The body houses the sealing element and serves as the primary structural component of the BOP. It is designed to withstand high pressures and temperatures.

2. Rubber Packing Element

The packing element, made of durable elastomers, is the core sealing mechanism. It expands and contracts to form a tight seal around the drill string or the wellbore.

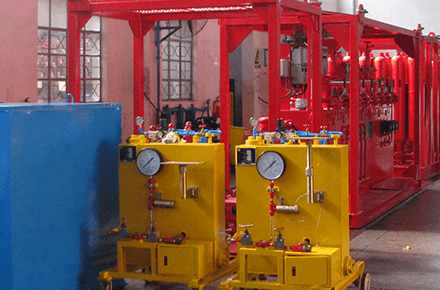

3. Hydraulic System

The hydraulic system provides the force required to compress or release the packing element. Controlled via an accumulator unit, it ensures precise operation under various well conditions.

4. Bonnet

The bonnet covers the top of the BOP and allows access for maintenance or replacement of the packing element.

The operation of an annular BOP is straightforward yet highly effective:

Activation: When wellbore pressure rises or a potential blowout is detected, the hydraulic system activates the packing element.

Sealing: The packing element expands to seal the wellbore completely, accommodating various equipment profiles or open-hole conditions.

Pressure Control: By maintaining a robust seal, the annular BOP prevents the escape of pressurized fluids and gases, ensuring safety and control.

Release: Once the pressure stabilizes or the operation concludes, the hydraulic system retracts the packing element, restoring normal drilling operations.

Annular BOPs are widely used in several critical drilling scenarios:

Routine Well Control: Managing wellbore pressure during normal drilling operations.

Kick Detection: Sealing the wellbore when unexpected pressure surges occur, indicating a potential influx of formation fluids.

Diverter Systems: Diverting mud or gas flow safely during specific drilling operations.

Stripping Operations: Allowing controlled movement of the drill string while maintaining a seal.

Annular BOPs offer several benefits that make them indispensable in the oil and gas industry:

Versatility: Capable of sealing around various pipe sizes or even an open hole.

Reliability: Designed to handle high-pressure scenarios with precision.

Ease of Maintenance: Modular components simplify repairs and replacements.

Compact Design: Occupies less space compared to some ram BOP configurations.

While annular BOPs are highly effective, they are not without limitations:

Wear and Tear: The rubber packing element is subject to wear, requiring regular maintenance or replacement.

Pressure Limits: Annular BOPs are generally less capable of handling extreme pressures compared to ram BOPs.

Cost: High-quality elastomers and hydraulic systems contribute to the overall expense.

In offshore drilling environments, the stakes are higher due to deeper wells, harsher conditions, and greater environmental risks. Annular BOPs play a critical role in subsea operations as part of the BOP stack, ensuring well control during deepwater drilling. Their ability to seal effectively under dynamic conditions makes them essential in preventing blowouts and mitigating risks.

Regular maintenance and inspection are crucial for the optimal performance of annular BOPs. Key practices include:

Visual Inspections: Regular checks for wear, damage, or leaks.

Pressure Testing: Verifying the sealing capability under simulated conditions.

Element Replacement: Periodic replacement of the packing element to maintain effectiveness.

System Calibration: Ensuring the hydraulic system operates within specified parameters.

The oil and gas industry continually seeks advancements to enhance safety and efficiency. Innovations in annular BOP technology include:

Improved Elastomers: Developing more durable and heat-resistant materials for packing elements.

Smart Systems: Integrating sensors for real-time monitoring and automated control.

Enhanced Hydraulic Systems: Designing systems with faster response times and greater precision.

The annular BOP is a cornerstone of well control in the oil and gas industry, offering unparalleled versatility and reliability. As drilling operations become more complex and demanding, the importance of robust safety mechanisms like the annular BOP cannot be overstated. By understanding its functionality, components, and applications, industry professionals can ensure safer and more efficient operations.

Whether onshore or offshore, the annular BOP continues to be a vital tool in safeguarding the integrity of oil and gas wells while protecting lives and the environment.

By continuing to use the site you agree to our privacy policy Terms and Conditions.