Drilling for oil and gas is a complex and high-risk operation that demands meticulous planning, advanced technology, and strict adherence to safety protocols. Among the myriad challenges that drilling engineers and operators face, preventing blowouts ranks among the most critical. A blowout, characterized by the uncontrolled release of oil, gas, or other fluids from a well, can have catastrophic consequences, including loss of life, environmental damage, and financial losses. In this article, we explore the strategies and best practices employed to prevent blowouts when drilling for hydrocarbons.

Before delving into preventive measures, it is essential to understand the factors that contribute to blowouts. Blowouts typically occur when the pressure exerted by the fluids in the formation exceeds the pressure exerted by the drilling fluid (mud) in the wellbore. This imbalance can result from various factors, including inadequate well control procedures, formation pressure fluctuations, equipment failure, or human error.

The consequences of a blowout can be devastating, with potential impacts on human safety, the environment, and the economy. In addition to the immediate risks posed to personnel on the drilling rig, blowouts can lead to oil spills, groundwater contamination, and damage to ecosystems. Furthermore, the financial costs associated with well control efforts, cleanup operations, and legal liabilities can be substantial, making prevention a top priority for drilling operators.

Preventing blowouts requires a multi-faceted approach that encompasses engineering controls, operational practices, and rigorous safety protocols. Here are some key strategies employed to minimize the risk of blowouts when drilling:

Well Design and Planning: The first line of defense against blowouts begins with comprehensive well design and planning. Engineers must carefully evaluate geological data, formation pressures, and wellbore stability considerations to design wells that can withstand the anticipated downhole conditions. Well trajectories, casing programs, and cementing strategies should be optimized to provide adequate barriers against fluid migration.

Drilling Fluid Management: Proper management of drilling fluids, or mud, is crucial for maintaining wellbore stability and controlling formation pressures. Drilling fluids serve multiple functions, including lubricating the drill bit, carrying cuttings to the surface, and exerting hydrostatic pressure to balance formation pressures. Engineers must select the appropriate type and properties of drilling fluid for the specific drilling environment and continuously monitor its performance to detect any signs of instability or influxes.

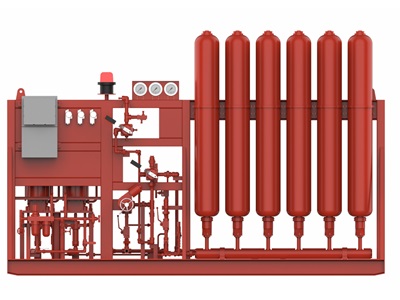

Pressure Control Techniques: During drilling operations, maintaining control of wellbore pressures is paramount for preventing blowouts. Operators employ various techniques, such as maintaining an appropriate mud weight, circulating bottoms-up regularly to remove gas influxes, and employing blowout preventers (BOPs) as a last line of defense. Managed pressure drilling (MPD) techniques, including constant bottomhole pressure (CBHP) and pressurized mud cap drilling (PMCD), offer advanced methods for controlling wellbore pressures in challenging formations.

Well Control Training and Procedures: Human factors play a significant role in blowout prevention, emphasizing the importance of well-trained personnel and robust operating procedures. Drillers, supervisors, and other personnel involved in drilling operations must undergo comprehensive training in well control principles, emergency response protocols, and equipment operation. Well control drills and simulations help reinforce safety awareness and preparedness for handling blowout scenarios effectively.

Real-time Monitoring and Surveillance: Advances in drilling technology have enabled real-time monitoring and surveillance of wellbore conditions, allowing operators to detect potential signs of instability or influxes promptly. Measurement-while-drilling (MWD) and logging-while-drilling (LWD) tools provide continuous data on downhole parameters, such as pressure, temperature, and formation properties, enabling proactive decision-making and risk mitigation.

Preventing blowouts when drilling for oil and gas requires a comprehensive and integrated approach that combines engineering expertise, operational excellence, and a strong safety culture. By implementing stringent preventive measures, including well design optimization, drilling fluid management, pressure control techniques, and personnel training, operators can minimize the risk of blowouts and ensure the safety and sustainability of drilling operations. As the industry continues to evolve and face new challenges, ongoing innovation and vigilance will remain essential for preventing blowouts and safeguarding the environment and communities.

By continuing to use the site you agree to our privacy policy Terms and Conditions.