The oil and gas industry's commitment to operational safety is epitomized by the meticulous design and implementation of Blowout Preventer (BOP) systems. These critical components serve as the last line of defense against uncontrolled wellbore releases, highlighting their indispensable role in safeguarding personnel, the environment, and infrastructure. This comprehensive guide embarks on a detailed exploration of BOP systems, shedding light on their diverse types, key components, maintenance protocols, industry challenges, and ongoing innovations.

At the core of wellbore safety lies the intricate engineering of Blowout Preventers. These systems are purpose-built to control and seal wells during drilling or production operations, mitigating the risks associated with blowouts. A blowout, marked by the uncontrolled release of hydrocarbons, poses not only environmental threats but also severe hazards to human life and critical infrastructure.

Versatility defines ABOPs, equipped with a flexible sealing element that adapts to various wellbore conditions. The annular design allows for effective pressure control and sealing.

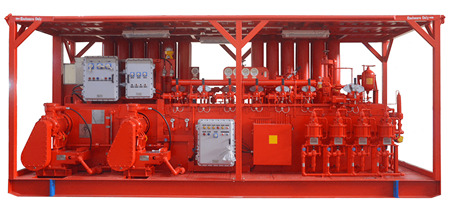

Harnessing hydraulic power, RBOPs utilize rams to seal the wellbore, providing a robust defense mechanism. The versatility of rams allows for specific functionalities, including emergency drill pipe shearing and sealing around irregular wellbore shapes.

The integration of both annular and ram blowout preventers in dual systems exemplifies a commitment to redundancy. This redundancy enhances operational safety, offering a fail-safe mechanism in case of component failure.

Functioning as the nerve center, the hydraulic control system enables remote BOP operation, ensuring rapid responses in emergency scenarios.

The accumulator unit serves as a critical backup, storing hydraulic fluid under pressure to power BOP components in the event of a power failure.

Strategically positioned control pods and manifolds facilitate the coordinated distribution of hydraulic power, optimizing control and monitoring capabilities.

Adhering to rigorous maintenance and inspection protocols is a cornerstone of ensuring the unwavering reliability of Blowout Preventer (BOP) systems. The industry's commitment to safety is epitomized by adherence to standards set forth by renowned organizations like the American Petroleum Institute (API). These standards delineate comprehensive testing and maintenance schedules, encompassing regular inspections and thorough assessments. The meticulous implementation of these protocols guarantees that BOP systems are in optimal condition, ready to function seamlessly when the stakes are at their highest during drilling or production operations.

The dynamic landscape of the oil and gas industry continually presents challenges that serve as catalysts for innovative advancements in BOP technology. One significant challenge is the constant need for improved reliability, given the critical nature of BOP systems in preventing wellbore disasters. Innovations are targeted at enhancing response times and ensuring adaptability to diverse wellbore conditions. Remote monitoring and predictive maintenance technologies stand out as transformative tools in this landscape, offering real-time insights into the health of BOP systems. These advancements not only elevate operational efficiency but also contribute to proactive risk management, minimizing the potential for unforeseen failures.

As frontline defenders against wellbore disasters, personnel engaged in drilling and production operations play a pivotal role in the effective operation and maintenance of BOP systems. Specialized training programs, meticulously designed and aligned with industry standards, equip individuals with the requisite skills and knowledge. These programs cover a spectrum of topics, including the intricacies of BOP operation, emergency response procedures, and the nuances of routine maintenance. Certification requirements ensure that personnel are not only well-versed in theoretical knowledge but also proficient in the practical aspects of operating and maintaining BOP systems effectively.

This exhaustive exploration illuminates the indispensable role played by Blowout Preventer systems in upholding safety standards within the ever-evolving oil and gas industry. Beyond the foundational understanding of diverse BOP types and key components, the holistic grasp extends to the critical importance of meticulous maintenance protocols, the perpetual challenges addressed through innovative solutions, and the expertise cultivated through rigorous training and certification. As the industry advances, the unwavering commitment to continuous improvement remains paramount, ensuring that Blowout Preventers stand as stalwart guardians of personnel safety and environmental integrity in the face of evolving challenges.

By continuing to use the site you agree to our privacy policy Terms and Conditions.