In modern oil and gas drilling operations, safety, performance, and reliability are the pillars of success. As exploration ventures into deeper, more geologically complex, and high-pressure reservoirs, maintaining control over wellbore pressure becomes increasingly critical. Central to this control is the Blowout Preventer (BOP)—a system designed to stop uncontrolled fluid flow from the well. While much attention is often given to the BOP hardware itself, one vital component that ensures its reliable operation is often overlooked: the BOP control system fluid.

This specialized hydraulic fluid plays a critical role in activating, lubricating, and preserving the functionality of BOP systems. Its composition, stability, and performance directly impact operational safety and efficiency. In this article, we explore how BOP control system fluid enhances drilling safety, improves performance, and contributes to sustainable well control practices.

A Blowout Preventer (BOP) is a high-pressure safety device installed at the wellhead to prevent uncontrolled releases of oil, gas, or other wellbore fluids. During drilling, workover, or well testing operations, the BOP can seal off the well in the event of a "kick" or pressure anomaly.

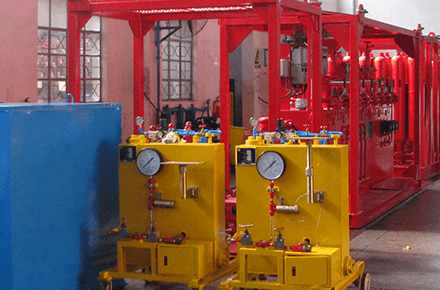

The BOP control system—consisting of control panels, hydraulic power units (HPUs), accumulators, and pilot valves—delivers the command signals and force necessary to actuate the BOP rams or annular preventers. These systems rely on high-performance hydraulic fluids to transmit pressure and operate reliably under extreme conditions.

Without clean, stable, and properly maintained control fluid, the responsiveness and integrity of the BOP system can be compromised, risking blowouts, equipment failure, and environmental disasters.

BOP control system fluid is a specially formulated hydraulic fluid used to power the actuation of blowout preventers and other associated valves. It is engineered to perform in high-pressure, high-temperature (HPHT) environments and must remain stable over long periods, even in subsea installations where maintenance is limited.

Key characteristics of an ideal BOP control fluid include:

High thermal and oxidative stability

Low compressibility and excellent lubricity

Low pour point for cold weather performance

Compatibility with elastomers and metals used in the control system

Non-toxic and environmentally safe, especially for offshore use

These properties ensure that the fluid performs reliably, even when exposed to extreme operational and environmental conditions.

A BOP system is only as dependable as the hydraulic fluid driving it. High-quality BOP control fluids contribute significantly to drilling safety in several ways:

1. Reliable Well Control in Emergencies

In the event of a pressure kick or well control emergency, rapid closure of the BOP is essential. The fluid’s compressibility and viscosity must remain consistent to ensure that rams or annular elements seal correctly and promptly. Fluids with poor flow characteristics can delay actuation or result in incomplete sealing—outcomes that are simply unacceptable in a critical situation.

2. Preventing Equipment Failure

Subpar hydraulic fluids can cause internal wear, corrosion, or varnish build-up within the control system. Over time, this degrades seals, cylinders, and valves, increasing the risk of mechanical failure. Quality fluids contain anti-wear and anti-corrosion additives that protect internal components, extending the service life of the BOP system.

3. Maintaining Control at Subsea Depths

In deepwater operations, the control system may be located thousands of meters below the surface. The hydraulic fluid must retain its properties at extreme pressures and near-freezing temperatures. Fluids that freeze, expand, or become viscous at low temperatures can prevent proper functioning of the subsea BOP system. Premium control fluids are specially designed for such harsh environments.

Beyond safety, BOP control system fluids also contribute to drilling performance by reducing downtime, simplifying maintenance, and enabling better system diagnostics.

1. Reduced Downtime from Failures

A compromised control system fluid can cause sticky valves, delayed ram operation, or erratic pressure signals. These issues lead to costly rig downtime while troubleshooting or replacing components. Fluids engineered for long-term stability and cleanliness reduce the frequency of such interruptions.

2. Improved Maintenance Intervals

Advanced BOP fluids exhibit resistance to oxidation, hydrolysis, and microbial contamination. This minimizes fluid degradation over time and helps maintain a clean system. As a result, maintenance intervals can be extended, allowing for more efficient and predictable drilling schedules.

3. Enabling Automation and Digital Monitoring

Modern rigs often feature real-time BOP diagnostics and remote operation systems. The performance of these digital systems is directly tied to fluid integrity. Stable fluid pressure and consistent actuation response are required for sensors and control units to function accurately. Clean, high-quality control fluid supports the automation and digitization of well control operations.

With growing emphasis on environmental responsibility, particularly in offshore drilling, eco-friendly BOP control fluids have become a priority. Many fluid manufacturers now offer biodegradable, non-toxic formulations that meet international environmental standards such as OSPAR and EPA guidelines.

Benefits of using environmentally responsible control fluids include:

Reduced risk to marine life in case of leaks or discharges

Simplified regulatory compliance

Improved ESG (Environmental, Social, and Governance) ratings for operators

These sustainable fluids perform just as effectively as traditional petroleum-based fluids but offer reduced environmental impact—a win-win for safety and sustainability.

To get the most from BOP control system fluids, operators should follow strict management and maintenance practices:

Regular Fluid Analysis: Periodic testing of fluid samples can reveal contamination, degradation, or additive depletion.

Filtration and Fluid Conditioning: Continuous filtration systems help remove particulates and maintain cleanliness.

Temperature and Pressure Monitoring: Ensuring fluid operates within the designated parameters prevents thermal breakdown or cavitation.

Proper Storage and Handling: Fluids should be stored in clean, dry conditions, and care should be taken during transfer to prevent contamination.

These practices ensure that the BOP system remains responsive and reliable throughout the drilling campaign.

The future of BOP control system fluids is closely tied to advancements in deepwater drilling, automation, and real-time well control. Ongoing innovations include:

Nano-enhanced fluids that offer superior thermal and anti-wear performance

Smart fluids embedded with diagnostic properties for system health monitoring

Synthetic base stocks with extended service life and lower environmental footprint

As the industry pushes toward digital oilfields and unmanned operations, the role of intelligent, stable, and environmentally friendly BOP fluids will become even more prominent.

While often operating in the background, BOP control system fluid is a critical enabler of safety and efficiency in drilling operations. Its performance directly influences the speed, reliability, and accuracy of one of the most important safety systems on the rig. By investing in high-quality, well-maintained fluids, operators can reduce risk, enhance operational uptime, and support sustainable practices.

As drilling challenges grow, so too does the importance of every detail in the system—and BOP control fluid is no exception. It’s not just hydraulic oil; it’s the lifeblood of well control.

By continuing to use the site you agree to our privacy policy Terms and Conditions.